Shuttering System

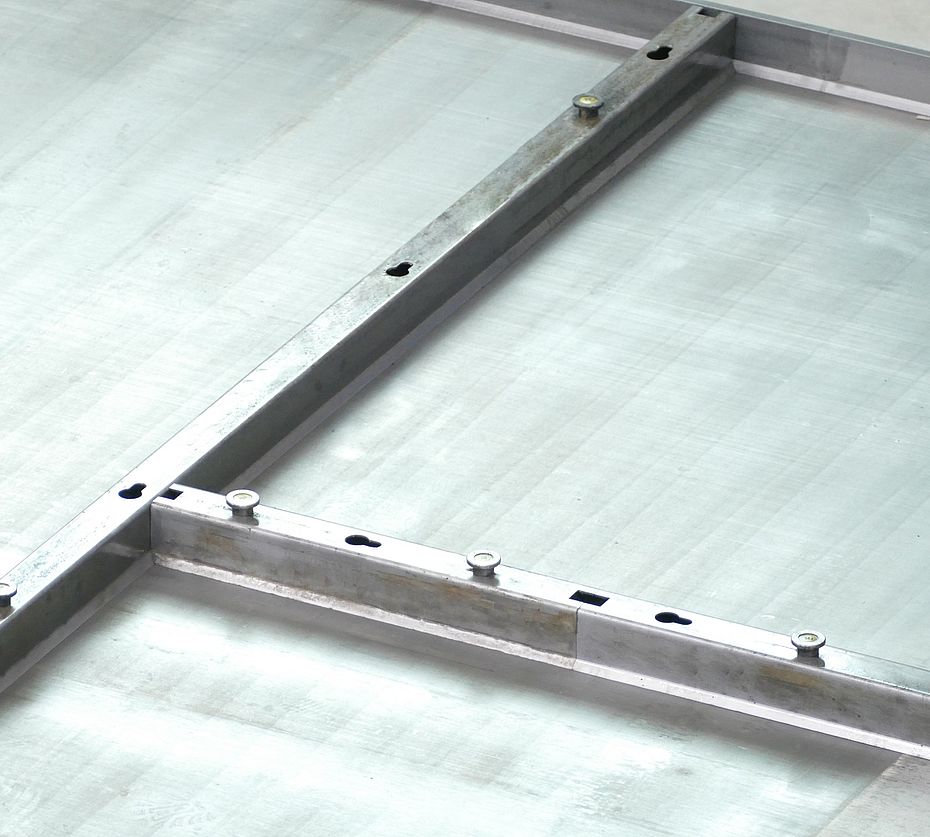

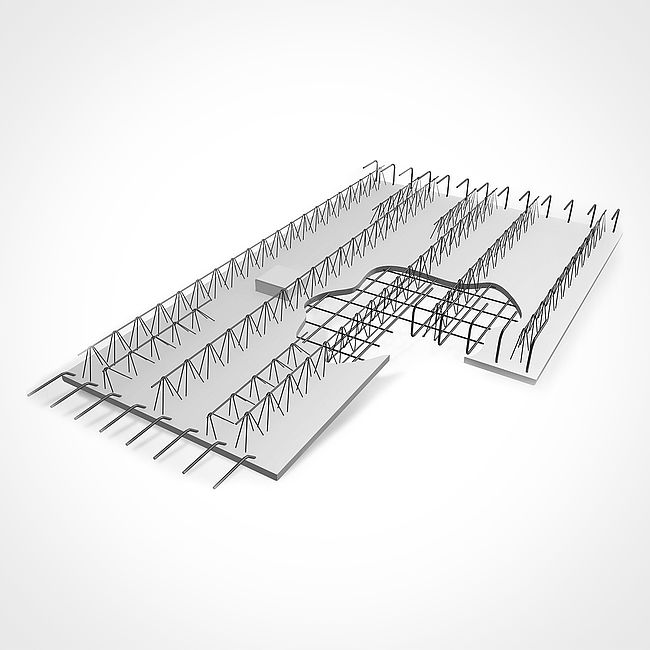

An efficient shuttering system lies at the core of any fully automated precast plant. The innovative, patented Infinity Line® shuttering system makes it possible for the first time to shutter without using filling materials and to reduce the number of shutters to a minimum. The notch-free system also makes it possible to shutter without bevelled notches. Additional costs for shuttering are therefore minimal.

Infinity Line® not only largely simplifies and reduces the cost of the shuttering process; it also improves the quality of the finished product. With the removal of the need for polystyrene panels and bevelled notches it becomes possible to produce perfect outer edges.

Shuttering process

The shutters are positioned automatically by the shuttering and deshuttering robot. As an alternative the shutters can also be placed manually. Magnets ensure that fixing is speedy and secure. Shutters for the production of lattice girder floors, sandwich walls and double and solid walls are available and can be produced to customers' specific requirements.

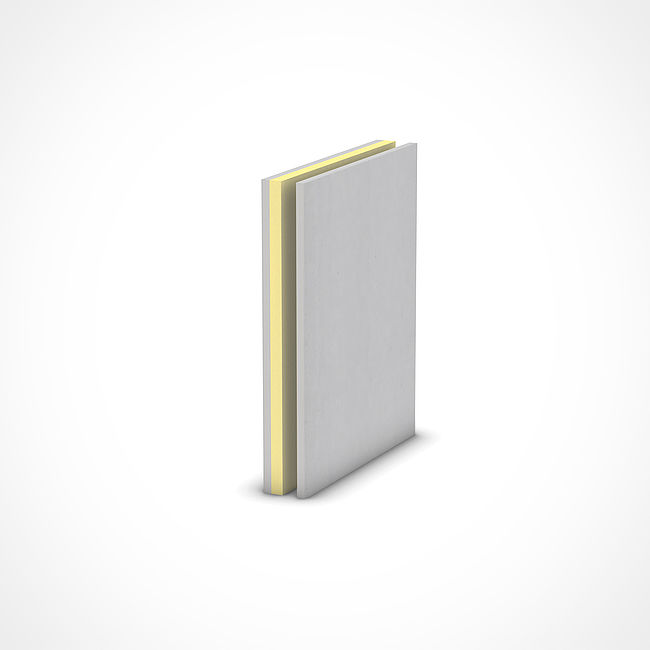

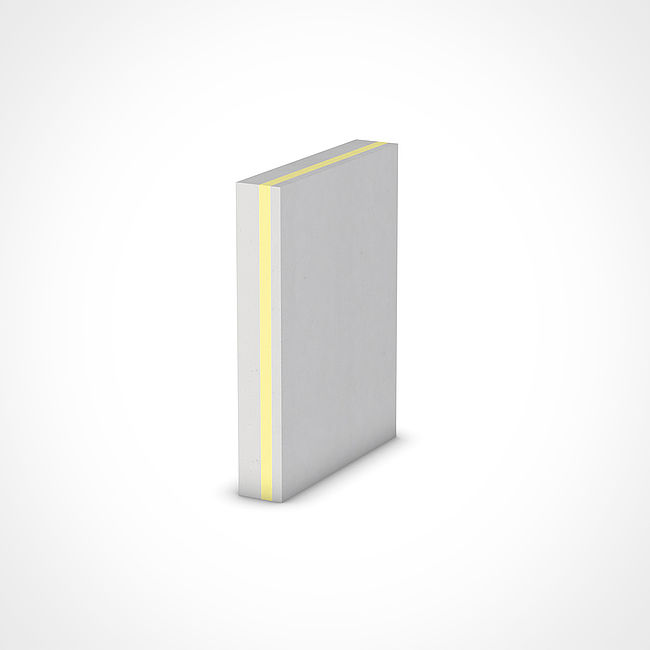

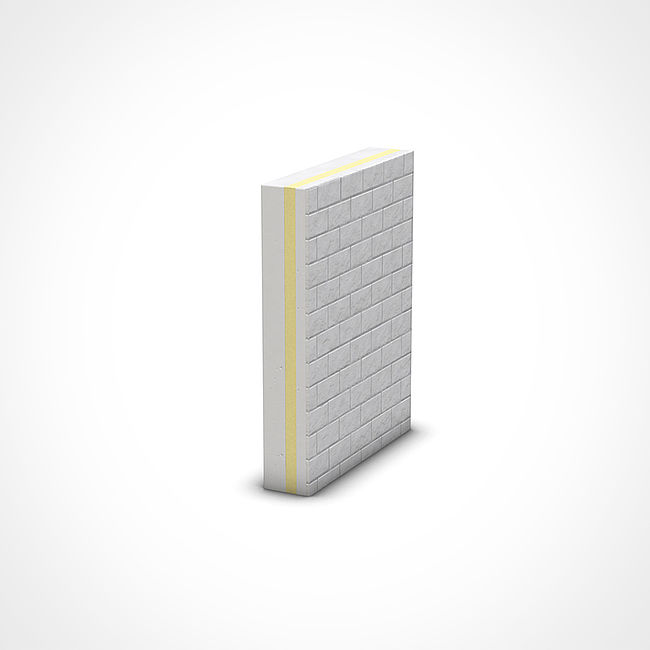

Mounting systems for solid wall shuttering

Solid wall shutters can be quickly and easily converted to the production of sandwich walls. Height and contours can also be adjusted, which makes the system even more flexible.

Shuttering adapters

A versatile range of solutions for adapting the production processes for solid walls and for producing window shutters and edges reduces costs and guarantees a high degree of flexibility.

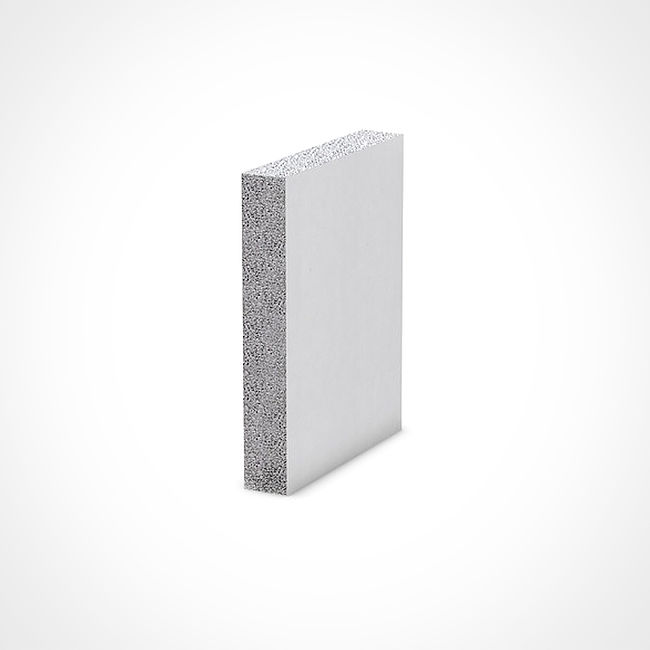

Notch-free shuttering process without filling elements

Perfect outer edges with notch-free system