Production Pallet

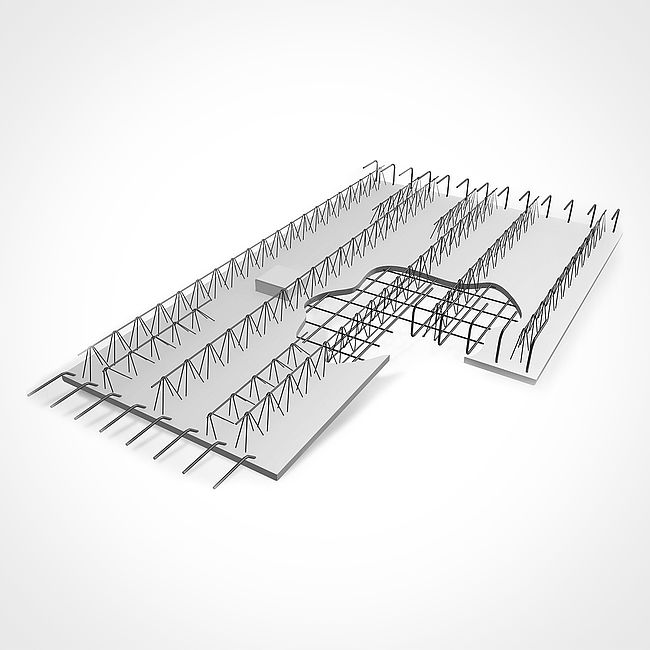

The production pallet provides the subsequent precast concrete panel and thus determines the quality of the end product. It passes through the various stages of manufacture in the production of concrete components, starting with the shuttering of the pallet up to the removal of the cured concrete element and is individually planned and manufactured for your production processes.

Exceptional quality end products

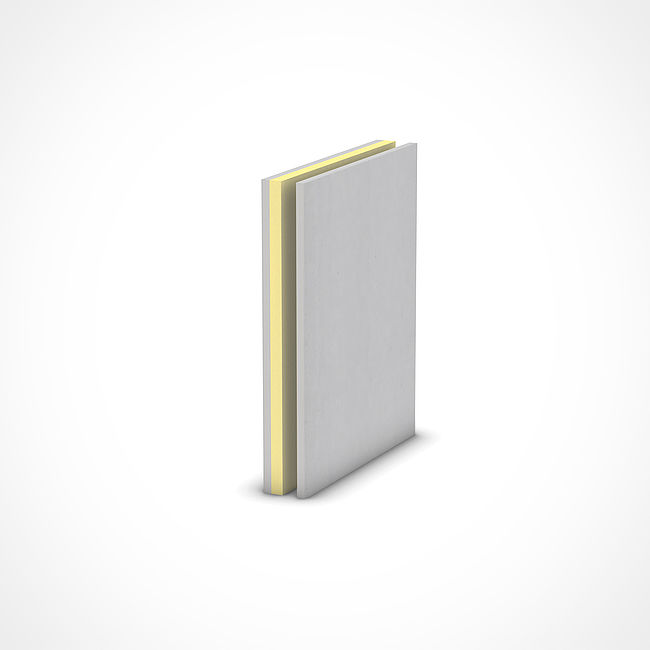

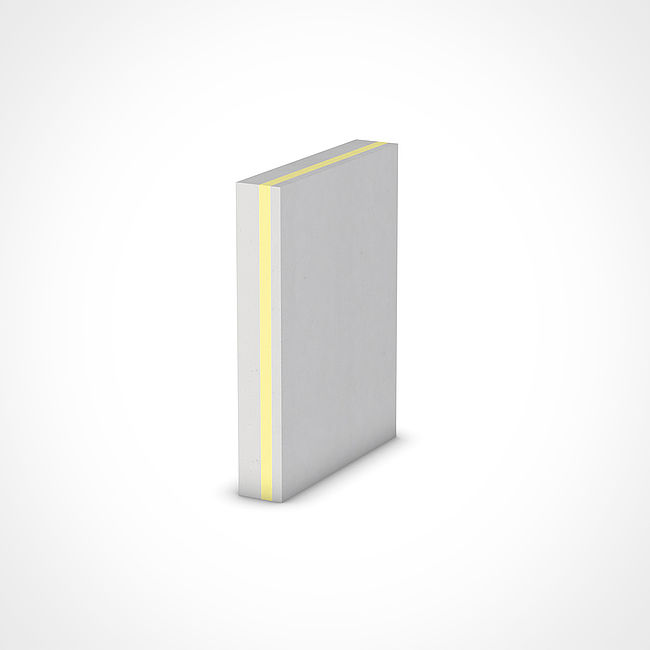

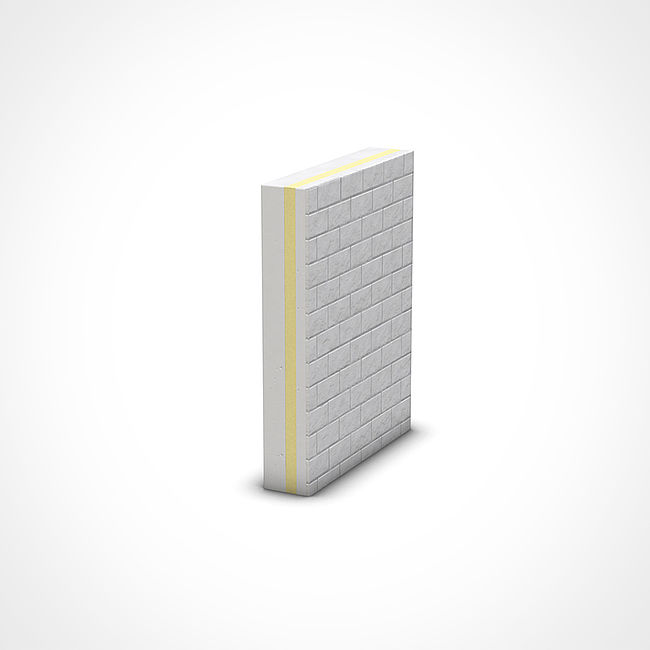

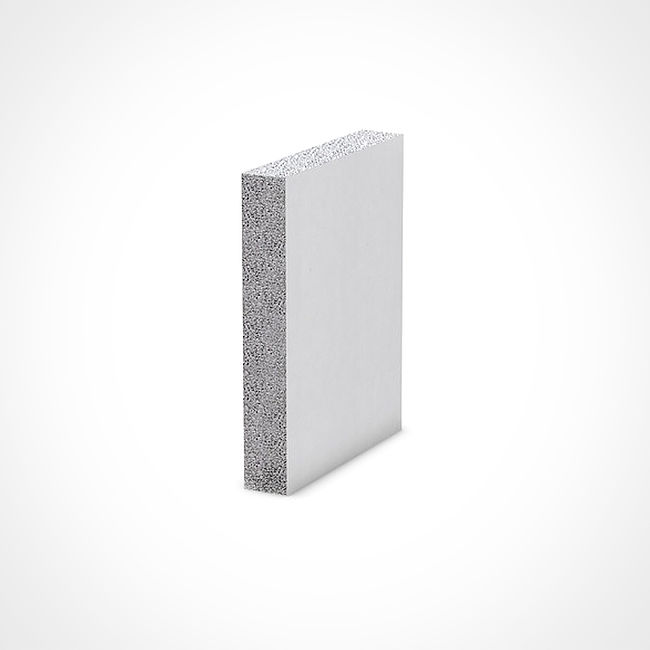

The production pallet consists of a painted shake-proof welded steel structure with a polished smooth mould surface. Since the surface of the mould has a substantial effect on the quality of the subsequent concrete panel, take advantage of our ingenious, specialised grinding process. Our pallets will enable you to manufacture precast concrete elements with a perfect exposed concrete surface. The undersides of the pallets are sealed with a special grey, two-component corrosion-resistant paint, which guarantees a high resistance to rust.

Manufactured individually for you

You tell us which elements you want to manufacture and we submit you an individual offer for suitable pallets. You decide the size, colour, load and side shuttering. We calculate our best prices for the shortest possible delivery period. If required, the pallets can be designed, for example, with stacking feet or coupling units.

Alternative manufacturing methods

As an alternative, the pallet can also be used in stationary production or as a production bed in the desired length. Depending on customer request we offer the beds with a compaction and/or heating system.

Consistent

Mould surface manufactured from one piece

High quality

Pallets with millimetre precision by reason of robot-supported manufacture with welding and grinding robots (NC-controlled)

Monitored

Measurement records for each pallet