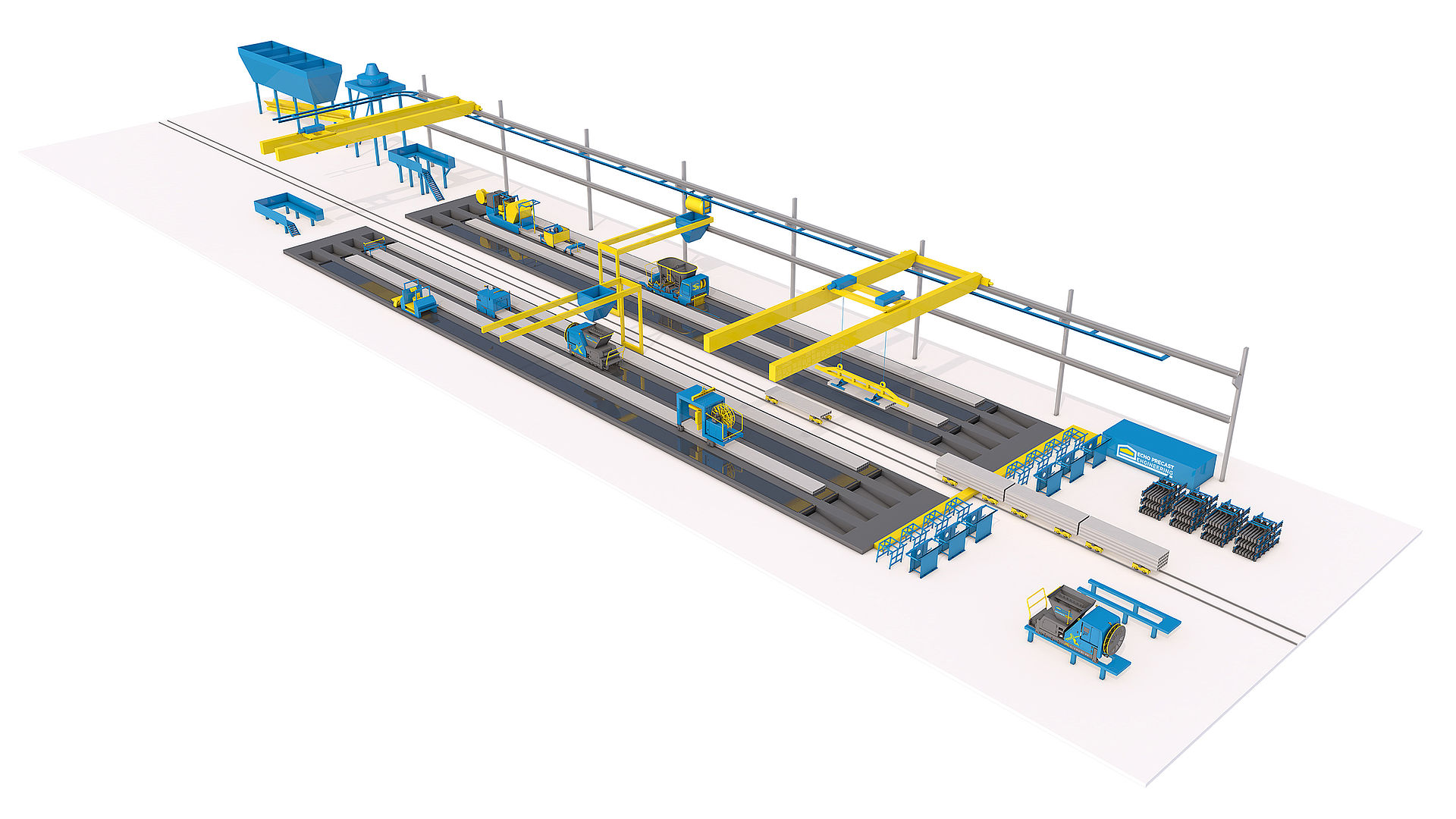

Plants for pre-stressed concrete elements

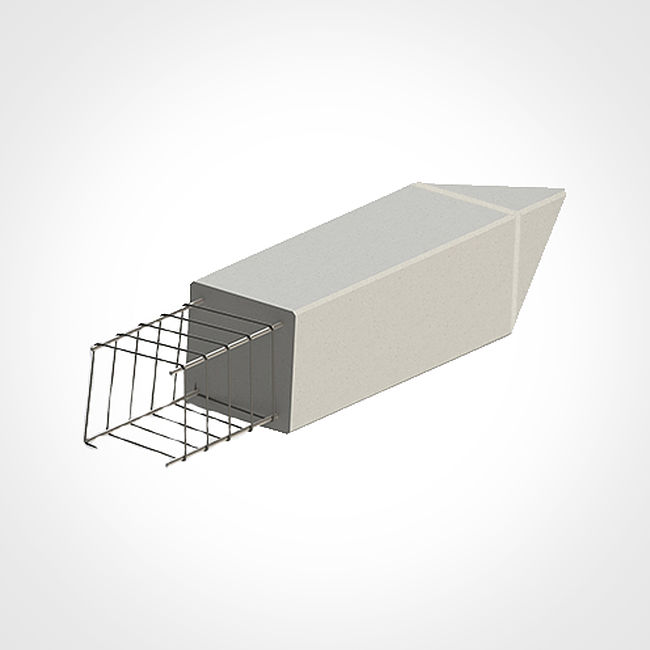

Hollow core slabs can be produced on traditional production beds, which are completely installed in the floor of the production hall and are not only durable, but also can be fitted with efficient, cost-effective heating systems. Another possible method of production of hollow core slab is mobile production beds, which offer the advantage that they can be dismantled and re-assembled in other production plants. The machines are supplied with concrete by a concrete spreader (portal or semi-portal).

The core of the production is either the Slipformer® S-liner for versatile, flexible production conditions or the Extruder X-Liner®, the innovative screw design of which makes the machine highly efficient.

Thanks to the automatic plotter it is possible to draw or print onto the concrete elements data, such as cutting angles. The multi-function trolley, the concrete aspirator, the fresh concrete saw and right-angle or multi-angle sawing machines for cured concrete ensure efficient preparation and smooth production processes. After the cutting process the panels are lifted out of the beds with the help of hoisting gear.

Benefits

Wide machine spectrum, customer-specific solutions:

The machines are suitable for production on beds 1.2 m, 1.5 m or 2.4 m wide. High degree of flexibility in cross-sections, more than only standard cross-sections possible.

Operator-friendly:

All the machines are operator-friendly, are easy to clean and require little maintenance.

Reliability thanks to our own testing facilities:

We are able to offer our customers the optimum solution for their production. Every machine is tested in our works prior to delivery. We are constantly developing our machines and thus expanding our own engineering knowledge in the field of hollow core slabs production. We are delighted to pass this added value directly on to our customers.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17