Carousel plant for double walls

The increased level of automation in carousel systems designed for the manufacture of double walls with or without insulation increases production throughput. The result is low cycle times and high quality final products.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Carousel systems designed for the production of double walls with or without insulation are usually highly automated. For example, shuttering robots, systems for manufacturing bespoke mesh and lattice girders, an automated placement of the reinforcement and an automatic concrete spreader are used.

Minimum cycle times, high output and consistently high quality for the final products are guaranteed by the high level of automation. Processes are optimised and use of manpower reduced.

The ebos® control system plays an important role in visualising and optimising production planning. To manufacture double walls the turning equipment turns the first skin as required over the freshly poured second skin.

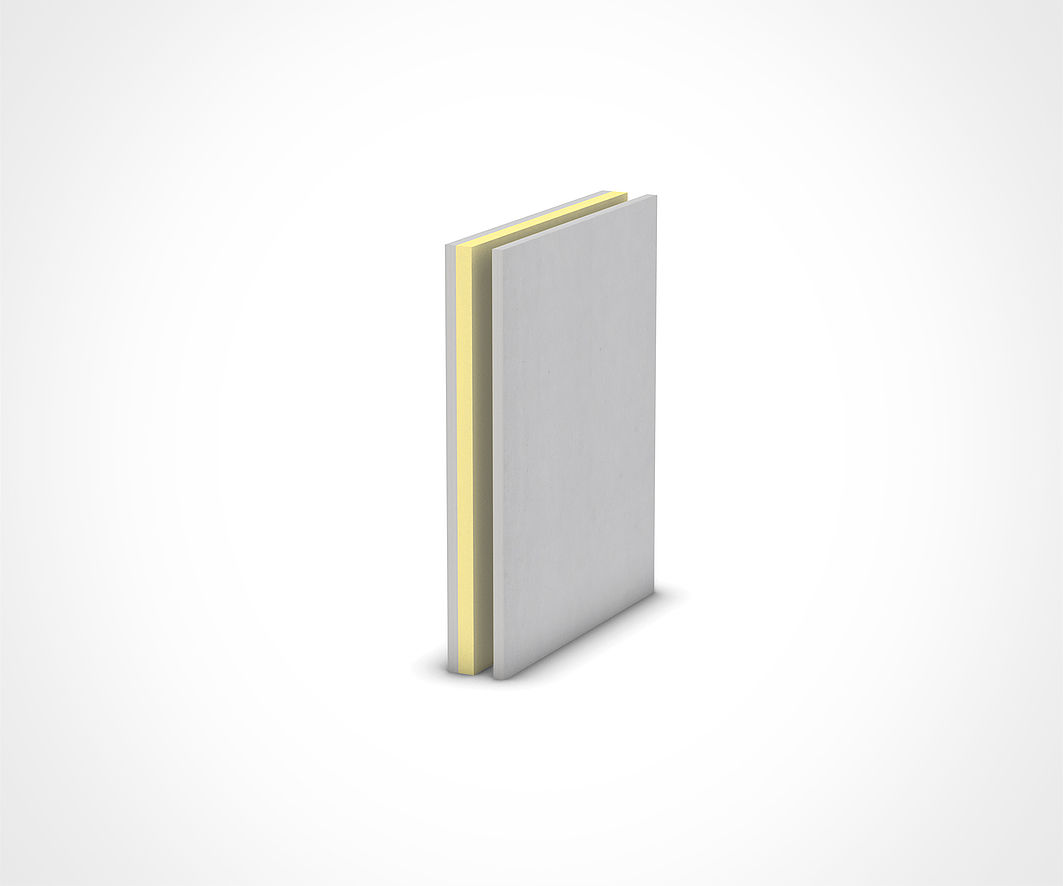

Double walls are produced, which are smooth on both sides and easy to manoeuvre; insulation can also be added. An insulation material cutter can be used to cut the required insulating material.