Turning equipment

When double walls are manufactured the cured first skin must be turned and set down above the freshly concreted second skin. This process is carried out by turning equipment. Depending on the design the turning equipment can turn the pallet as a whole including the concrete element or vacuum technology can be used to turn the concrete element, which has been removed from the pallet.

Turning process

The turning equipment turns the entire pallet with the cured first skin around and places it in a second pallet, where the freshly concreted second skin is located.

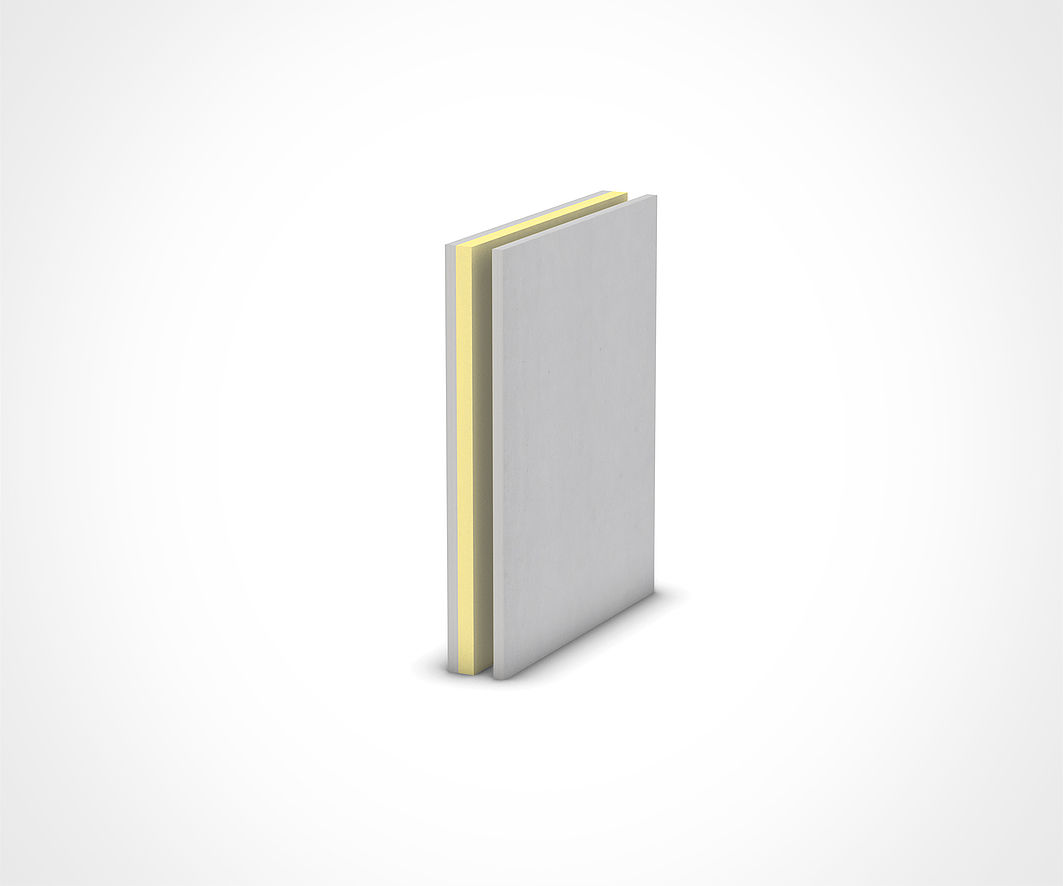

Formation of the double wall

The turning equipment also guarantees stability during compaction and in the process the upper plate is tensioned and fixed with holding-down clamps. In order to bring the pallet shutters with the first and second skins congruently over each other on the compaction station, two pallet guides have been attached to the turning frame. These are used to fix the inner edges of the pallet side shuttering above each other.

Adjustment of pallet distance

The automatic adjustment of pallet distance controls the distance between the pallet to be turned and the stationary pallet automatically and continuously. This removes the need for manual regulation of the thickness of the double walls by means of spacers. The holding-down clamps can be fitted with an additional system for automatic height adjustment for the production of insulated double walls.

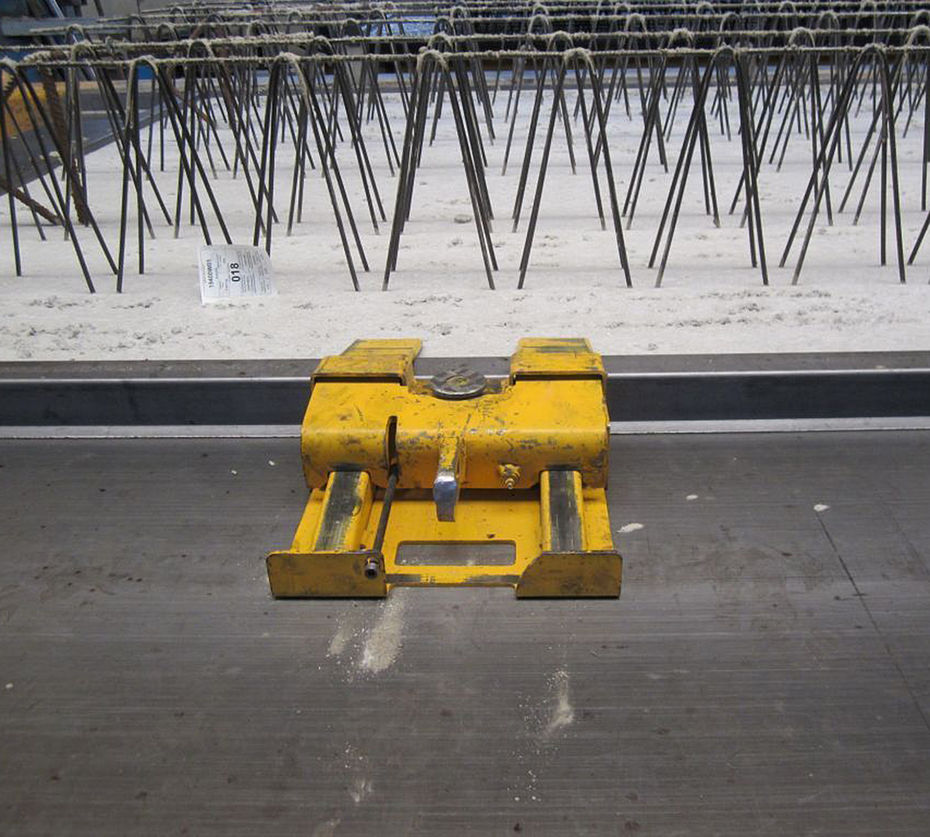

Double wall adapters

This special solution is used to manufacture double walls of a lower height. Since in these cases it is not longer possible to tension the upper plate by means of a conventional holding-down clamp system, adapters in the integral magnets are used to turn the double wall.

Vacuum turning equipment

In contrast to conventional turning equipment, the vacuum turning equipment directly turns the concrete element, which has already been removed from the pallet, places it in the prepared pallet and stabilises it during compaction.

Flexible production of double walls with or without insulation

Automatic adjustment of pallet distance saves costs

Improved ergonomics relieve the physical load