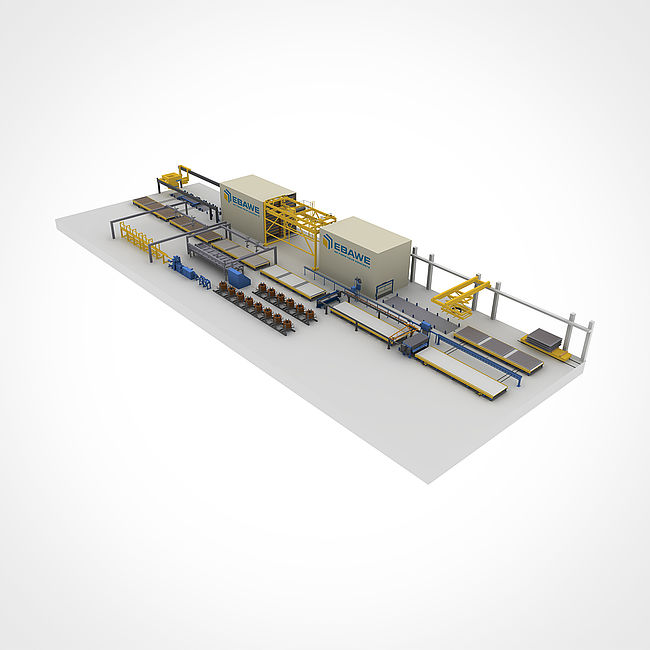

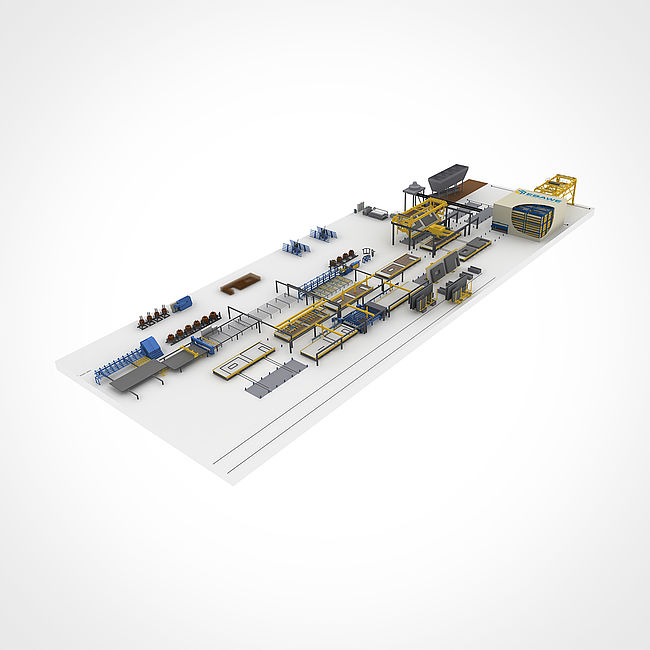

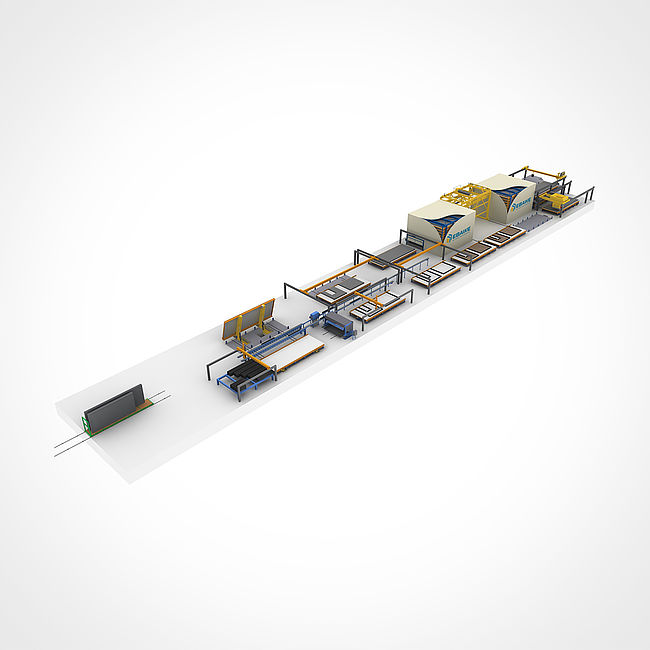

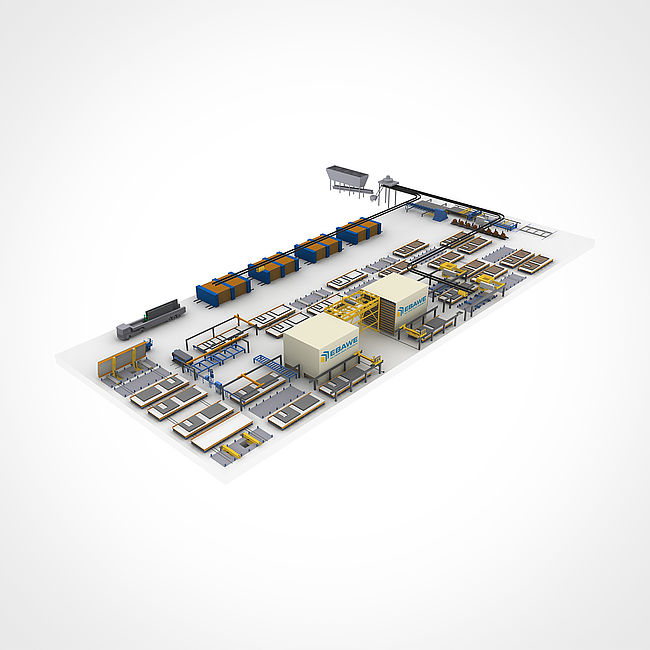

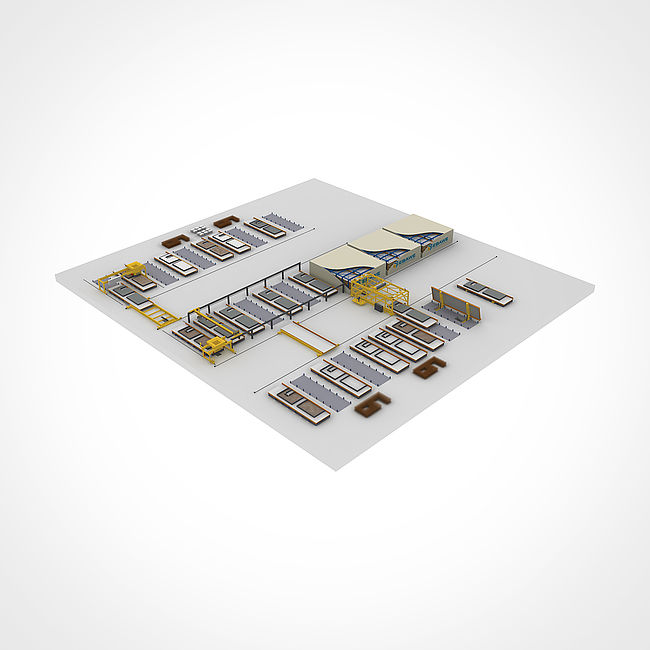

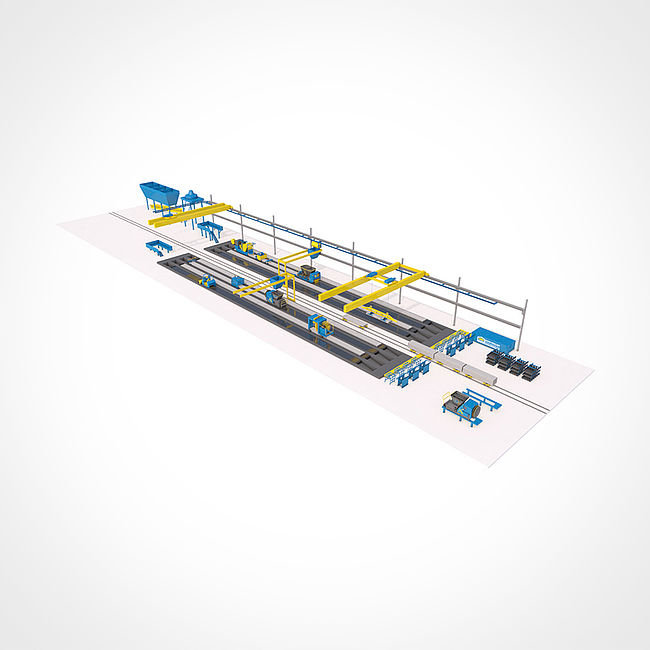

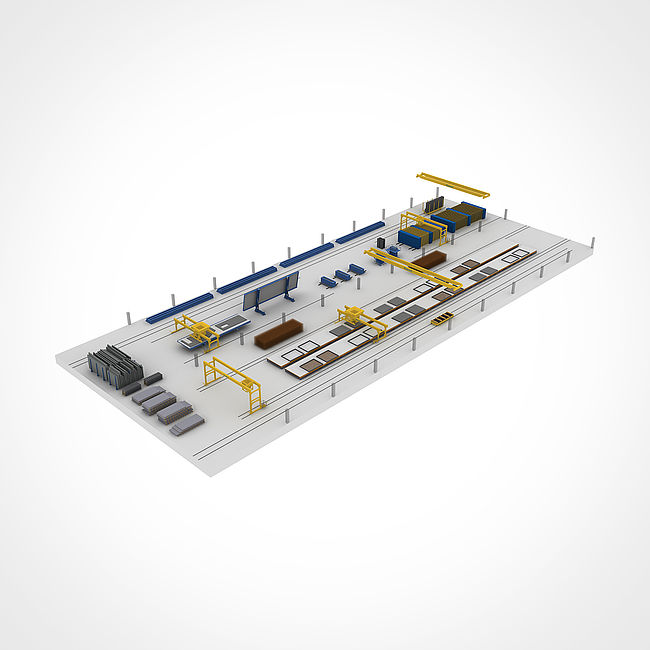

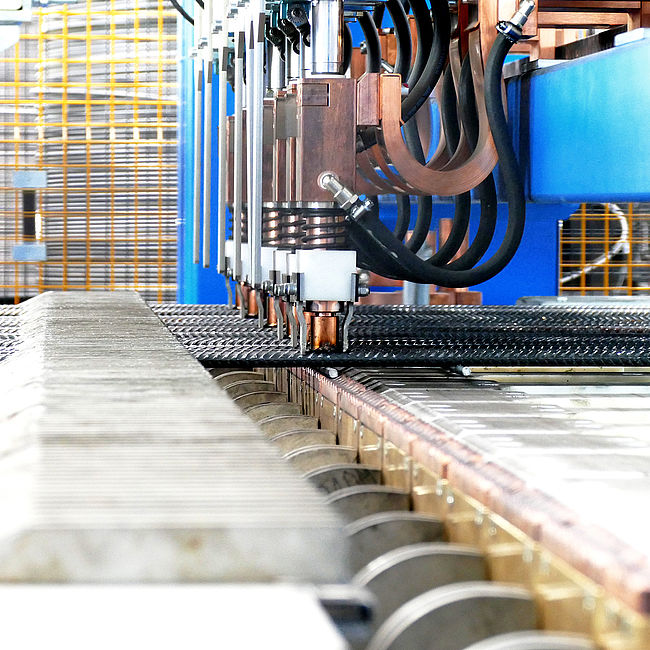

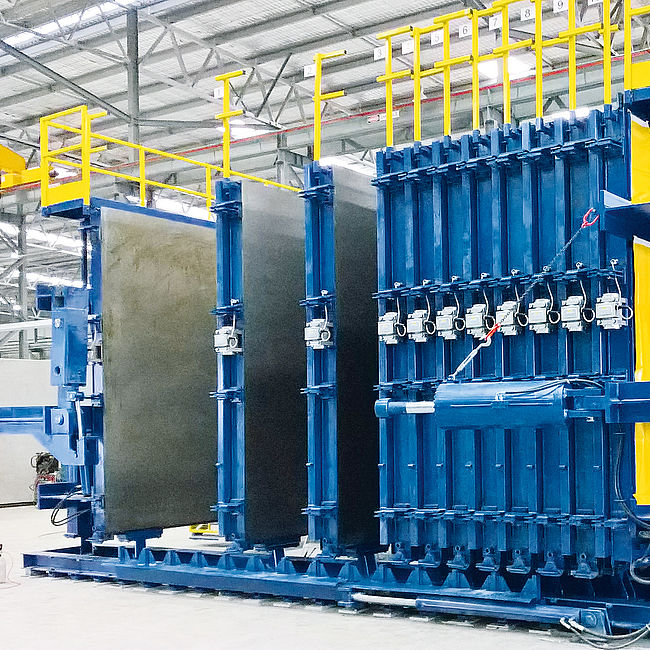

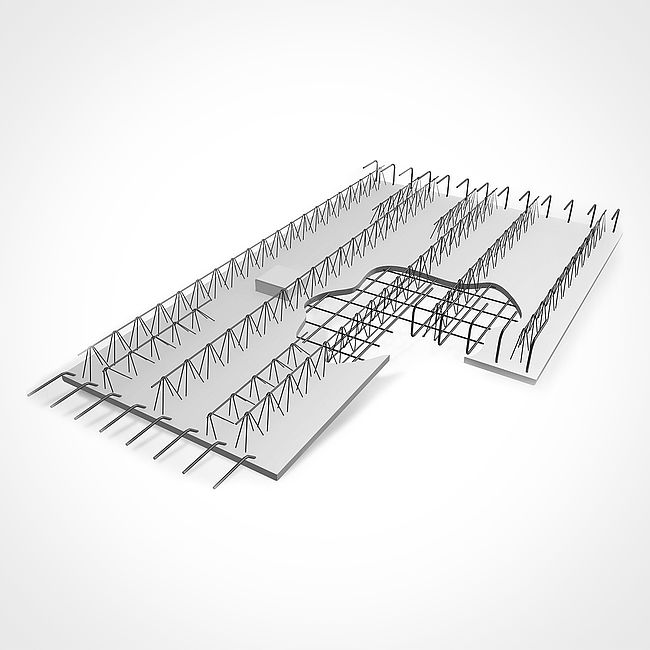

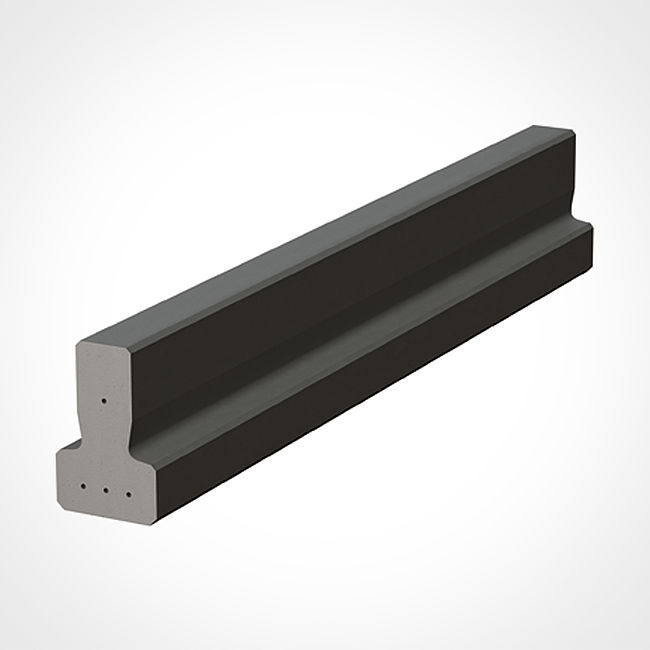

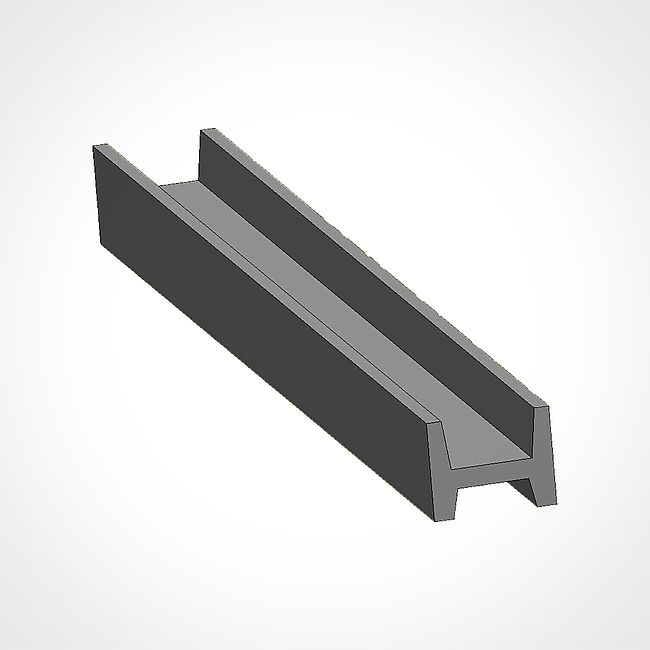

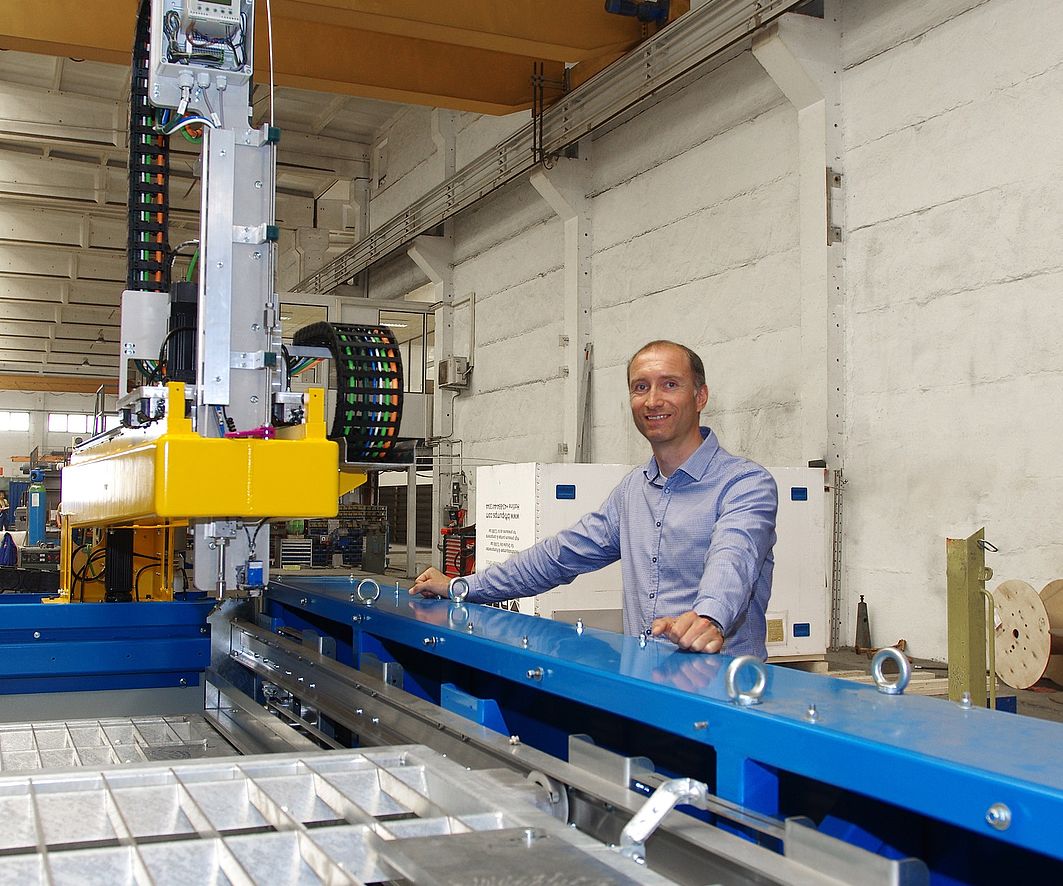

Plants for precast concrete elements

Flexible solutions from one source

EBAWE is your partner of choice for implementing turnkey production plants for precast concrete construction. As one of the world’s market leaders with more than 60 years of experience, we design industrial production units in accordance with the highest technical requirements. We provide our customers with tailor-made solutions for the manufacture of precast concrete elements.

Our vision: PEAK INNOVATION – PEAK PERFORMANCE – WORLDWIDE AHEAD